LTL is an industrial grade self-regulating heating cable that can be used for freeze protection of pipelines and vessels and also for snow and ice prevention on roofs and gutters.

The power output adjusts automatically in response to the ambient temperature.

Because of its self-regulating characteristics it will not overheat even when the cable is overlapped. This guarantees maximum safety and reliability.

The installation of LTL heating cable is quick and simple and requires no special skills or tools. Because of its parallel construction the heating cable can be fitted on site to exact length without any complicated design calculations.

Termination, splicing and power connection components are available in convenient kits.

| Rated voltage | 230 VAC |

|---|---|

| Maximum continuous operating temperature (trace heater energized) | 65 °C |

| Maximum continuous exposure temperature (trace heater de-energized) | 85 °C |

| Ambient temperature range | −60 ... +55 °C |

| Minimum installation temperature: Thermoplastic overjacket | −30 °C |

| Minimum bending radius | 25 mm |

| Maximum screen resistance | 18 Ohm/km |

| Maximum braiding resistance | 10 Ohm/km |

| Conductor cross-section | 1.00 mm2 |

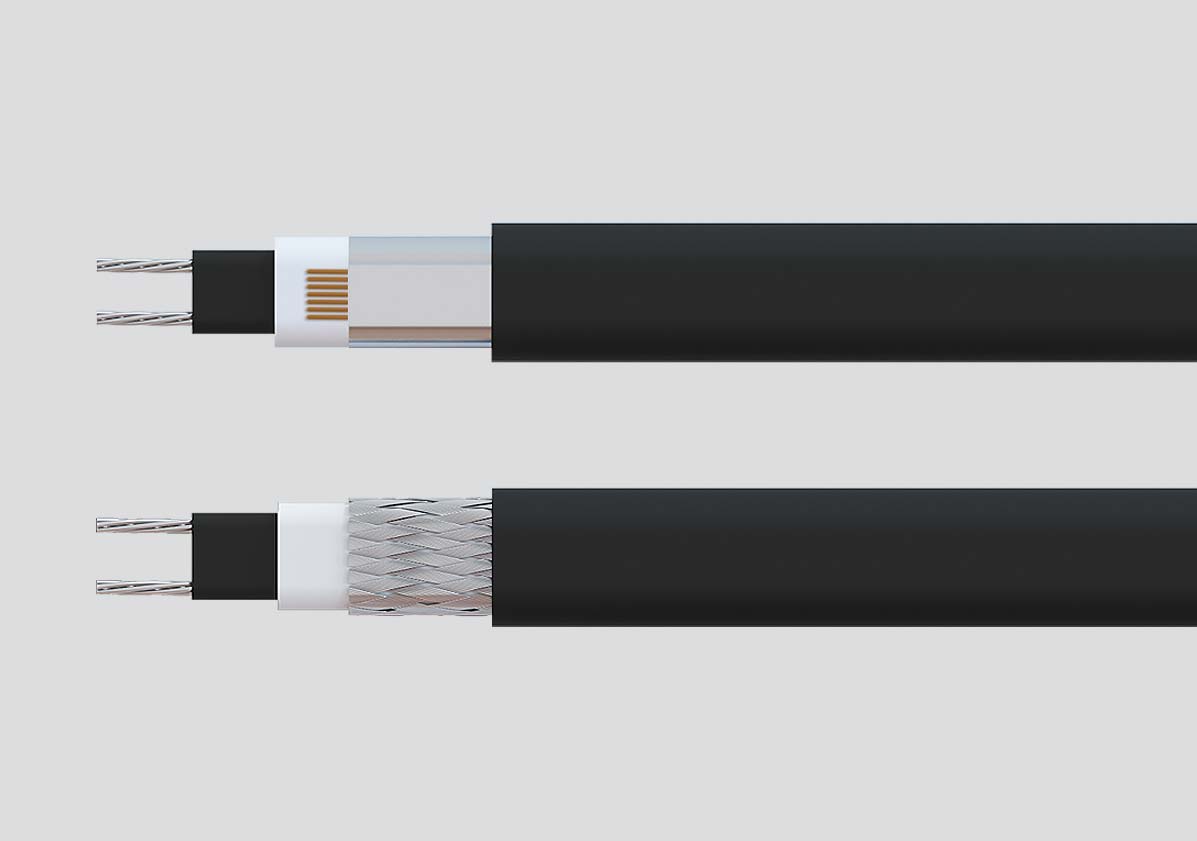

| Dimension: Thermoplastic elastomer overjacket, aluminum foil Thermoplastic elastomer overjacket, braiding |

10.20×5.70 mm 10.90×6.00 mm |

| Weight: Thermoplastic elastomer overjacket, aluminum foil Thermoplastic elastomer overjacket, braiding |

86 kg/km 113 kg/km |