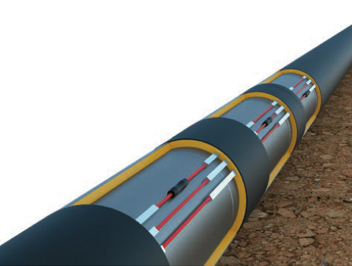

Heating of Extra-Long Pipelines: VeLL

VeLL heat tracing system is designed for temperature maintenance and freeze protection of long and extra-long pipelines in hazardous and non-hazardous areas.

- Heating of extra-long pipelines up to 150 km without supply network

- High operating temperature up to +200 °C

- High mechanical reliability of the heating system

- Electrical safety

- Easy and convenient installation

- Approved for explosive areas